“Over the years, when we faced a tough situation with a really angry customer, I always connected that person with Dean. He always knew what to do… how to listen to the customer and help them in every possible way.”

-Pam Cwikla, Arctic Cat employee

With more than four decades at Arctic Cat, all in the category of Service and Technical Training, Dean Lawrenz has experienced a lifetime of service-related challenges and satisfaction. Though he was unwilling to share his age, the spry Lawrenz (he still walks more than four miles a day) was gracious enough to answer some questions about his job and his years at Arctic Cat.

AI: What’s your job title, and then explain what you do on a daily basis?

Lawrenz: I’ve held many different Service training jobs during my time at Arctic Cat. Since 2000 I’ve been the International Service Technician, which consists of helping our overseas service and parts technicians with any challenges they’re dealing with. I spend my days on the phone and computer, communicating with these techs. I love my job… so much that when I’m forced to use my vacation days, I still pop in just to see what’s going on here. This place has been my life for four decades.

Lawrenz has been integral to the creation of many Arctic Cat service manuals, specification manuals, reference guides and other related information.

AI: What are some of the other jobs you’ve held?

Lawrenz: Well, my history in the powersports industry began when I moved to Thief River Falls in 1969 to work for Long Engineering, who was modifying the Hirth, Kohler and JLO engines for the Arctic Cat Factory Mod sleds. When Arctic Cat switched to Kawasaki engines in 1971, the chrome-plated cylinders put an end to Long’s mod shop, and I got a job with Cat in the Customer and Dealer Service Department. There were two of us whose job was to take calls from dealers and customers who had service or parts-related question.

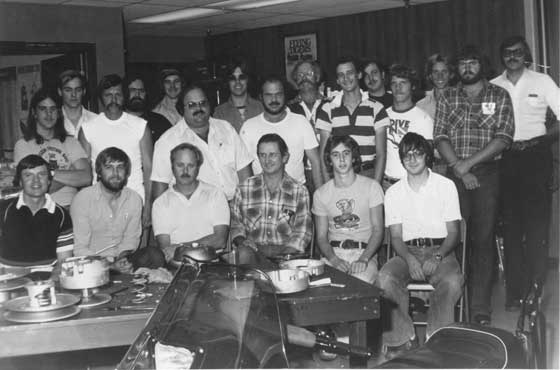

Dean is on the front row, far left of this photo from a 1978 Arctic Cat factory 4-day service seminar.

From 1973-1981 I did product service training seminars, as well as helping produce service manuals, reference guides, newsletters and training manuals.

I was the Service Manager from 1985 until getting my current role in 2000.

It’s been a lot of years, and I’ve loved every job I’ve had here.

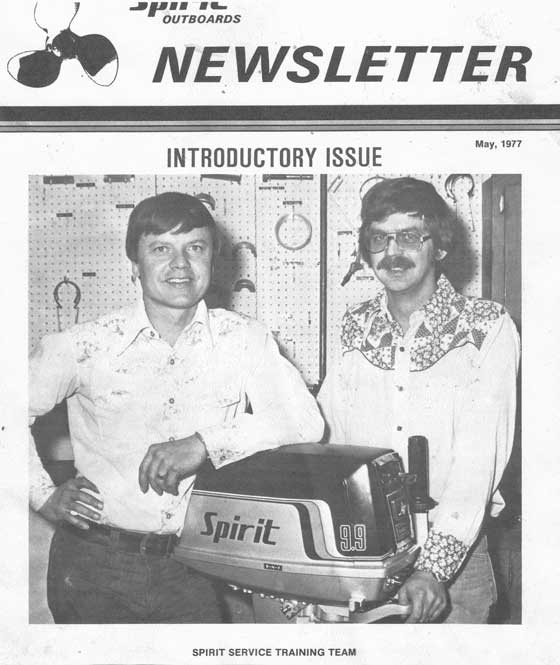

Dean Lawrenz (L) and Kent Espeseth from a 1977 issue of the Spirit Outboards Newsletter.

AI: That is a lot of years! What’s your employee number?

Lawrenz: I’m employee #102. There aren’t too many people still working here with a lower number than mine.

A reprisal of the famous Arctic Cat “condo crew,” taken in 1999 by C.J. Ramstad for the second edition of the LEGEND book. L-to-R: Brian Espeseth, Ole Tweet, Roger Skime, Dennis Zulawski, Dean Lawrenz and Dave Thompson.

AI: What did you do during Arctic Cat’s “Gone Fish’n” years of 1981-83?

Lawrenz: I ran the Cuyuna Engine Service Department in Crosby, Minn. They were still building engines for ultra-light aircraft.

I also bought the Lantern restaurant in Thief River Falls, which I continued to own until I sold it six years ago.

When Arctic Cat came back in 1983, my job was working with Brian Espeseth to take care of parts, put together service manuals, create service schools and of course work to resolve service challenges with dealers and customers. That was a very exciting and gratifying time.

An Arctic Cat “Shop Talk” column penned by Lawrenz in 1978.

AI: What part of your job gives you the greatest satisfaction?

Lawrenz: Being able to help our technicians resolve whatever challenges they face.

AI: What is the greatest challenge of your job?

Lawrenz: Often my greatest challenge is to understand exactly what the real issue is when talking with our overseas techs.

AI: Like many people at Arctic Cat, you’ve also been involved with racing over the years. Tell me about that.

Lawrenz: Well, like I said before, my first job was modifying the Arctic Cat Factory mod engines. Once I started working in Service, my racing efforts included prepping the I-500 cross-country race sleds that the Factory oval racers would compete on, like Larry Coltom and Bob Elsner. We’d have those sleds built and ready for them to race, and often the first time they rode those sleds was when the green flag dropped for the first day.

More recently, I helped wrench for Brian Espeseth’s kids when they raced, about four years ago.

It’s interesting, but I’d always get service questions from people who wanted to know if the set-up info that we gave out was really what the factory guys were using. It always was. We never withheld any information from our independent racers.

AI: Do you own snowmobiles and/or ATVs?

Lawrenz: I have a 1994 ZR700 that’s modified with twin pipes and engine porting. I usually ride around 1,000 miles a year. A favorite ride of mine is from my home, which is located on the Red River about one mile out of Thief River Falls, to the town of Trail, where they serve the best hamburgers that I know of. I’ll ride there for dinner, and then ride home.

AI: What’s your all-time favorite Arctic Cat and why?

Lawrenz: I have two: The 2012 F800 because it handles great and is fast; and the other is my ’94 ZR, which also handles well.

AI: Tell me a good Roger Skime story.

Lawrenz: I have known Roger for many years and he is really a good guy to work with. He works at full throttle and is always positive.

Dean talks with friend and co-worker, Pam Cwikla

Thanks for reading!

Very nice article – once again the best articles are the ones about the people at AC. Just once question/concern…. being that Dean is employee #102, shouldn’t he have a bigger space to work from??

Thanks Kevin, my favorite stories to create/share are also about people. It’s actually a blessing to be able to share these stories.

Arctic Cat is truly a company comprised of many genuine, amazing people, and Dean is one of them. A lifetime of dedication and enjoyment of his job… so much so that he still comes in on his day off (he’s been working Monday-Thurs. for a while now, but still comes in on some Fridays just to see what’s going on).

Not sure what to say about his crammed cube, but from what I know about Dean, it’s probably never crossed his mind that it’s too small. He’s a very gracious, grateful person.

Yeah, I was just kidding about the workspace. I do want to thank you for taking time to write about the people behind the great name!

To echo John – I’m a supplier to Arctic Cat and have made many many trips to TRF. My business is mainly automotive, but do supply some parts to the Powersports Industry.

The people at Arctic are the most genuine, gracious, nicest, hardest people working I deal with. Their enthusiasm for their product is awesome and it shows in their products / service.

In the summer, I race hydroplanes. My current boat has a F1000 twin in it. It’s one of a kind. But whenever I have a question about ANYTHING, I know I can pick up the phone and call Dale H., Greg S., Ryan H., etc. They are always most helpful. Without their advice and guidance, I don’t think I’d be where I am.

I usually laugh at people that are brand-loyal as I think competition is a great thing for progress. But the people like Dean and the rest of the crew in TRF keep me coming back to buy Cats.

Keep up the good work John!

Mom, is that an Arctic Cat smock you have on?? Typical, you & Deano sitting around getting nothing done!! You 2 are like fixtures there. Lot’s of old time stories to share. I wonder if I’d get my employee #409 back?

wow!!! Finally a story about Dean. I worked for and with Dean for about 30 years, and he is one of the hardest workers I know. If you drive by the factory late at night or on a Sat. or Sunday you more than likely will see his pick up there. He is the most honest and friendly person I’ve known. I don’t work for Arctic anymore, but when I do go over to the plant Dean and Gary Nelson are on my list to stop and say hi.

Dick

Awesome Sandberg! Great to hear from Dean. He is an inspiration. I always hit the Lantern a couple time a week back in the day!

And Dick, I always enjoy hearing your comments and thoughts!

Hi Deno. Say hi to Jan for me.

Auggie

My Dean Lawrenz story , Back in the winter of 1988-89 I was talking to Dean about some questions on my 650 wildcat. This was a Thursday night and I was telling Dean I was going on a three day ride. Dean asked if I had any issues with broken piston rings. I had not,but Dean suggested I look at them. Since it was so close to the weekend Dean offered to have me bring it to the factory . I drove about 75 miles met Dean and he proceded to take the top end apart. When the one piston released from the cylinder there was a broken ring in Dean’s hand . Dean was actually excided because there was people from Suzuki at the factory that day. Dean left the room to show them the broken rings. Long story short Dean got me going that day and turned my weekend into a 500 mile trouble free/ fun weekend. I can’t thank Dean enough for helping me that weekend. Thanks again!

Awesome story, Richard! Thanks for sharing that.

Artdcat: You better be careful, because your mom is going to be interviewed (soon) and she promised to provide baby pictures of her precious son.

I better stop commenting on Arctic Insider….

Hey why don’t you publish your phone number there’s a bunch of us 2012 owners that would like to speak to you!!!

I have had the pleasure of working with Dean on many projects over the years, whether it was checking out a part for him at the distribution center in Ohio, or helping him write the Quick Reference Guide that sits next to my desk. When I have a question about a part, or how something is put together Dean is always the first tech I call…I actually have him on speed dial. Hey Dean….thanks for dinner at the Lantern the last time I was there. Now it is your turn to come to Ohio.

Great to see you are still working with Arctic. Always enjoyed the service schools you put on. I missed the 50th Anniversary no place to stay. If I ever get back to Thief River Falls wil look you up.

Great to see you are still working with Arctic. Always enjoyed the service schools you put on. I missed the 50th Anniversary no place to stay. If I ever get back to Thief River Falls wil look you up.

I believe avoiding highly processed foods may be the first step to lose weight. They may taste excellent, but processed foods currently have very little nutritional value, making you take more to have enough power to get over the day. If you’re constantly ingesting these foods, changing to whole grain products and other complex carbohydrates will make you to have more power while having less. Great blog post.