Autumn was in full swing during my 2-day trip to Arctic Cat and Textron Off Road in Thief River Falls last week. I never get tired of walking into these doors and wish it would happen more often.

It’s always a surprise to see what’s on display in the lobby, from sleds and accessories to side-by-sides (and the classic Model 100 in the background).

The purpose of the trip was a meeting with engineers about the next model line of Arctic Cat snowmobiles. The agency and marketing team are already deep into preparing the materials and information that we’ll consume when the new models are introduced iater this winter.

It’s a bit weird to start wrapping my head around an upcoming model year line when the current model line is so fresh and new and not even yet on the snow. It can be REALLY weird for engineers, who are often working on models that are 2-3 years out, to bring their head back around to the models that are just hitting dealer floors. But that’s how product cycles move.

An impromtu hallway meeting with (L-to-R) Jared Spindler (Director of Product Strategy), Kale Wainer (Channel Marketing Manager), Craig Kennedy (Vice President) and Andy Beavis (Chief Mountain Engineer). Unplanned, brief conversations such as these can be serious, funny, strategic, insightful and more. They are almost always beneficial and part of the communication fabric of Arctic Cat.

I jumped into a special plant tour hosted by Mr. Versitle, Wes Selby (the rock star in the middle). Selby is awesome for all kinds of reasons, and his deep knowledge about the company’s production was yet another new one that was revealed to me on this trip.

I’ve had the great fortune to make hundreds of laps of the Arctic Cat/Textron production and assembly areas over the years, and each lap is special and enlightning in its own way. Seeing raw materials bent/welded/cut and otherwise turned into components, and then seeing complete machines emerge along the assembly lines, is so cranking cool! The logistics and process never ceases to amaze me.

Pieces that will soon become new ALPHA ONE suspensions.

Constructed of aluminum and magnesium, this single beam and the whole ALPHA ONE system is a revolution unfolding in real time.

Soon-to-be bumpers, A-arms, chassis and more.

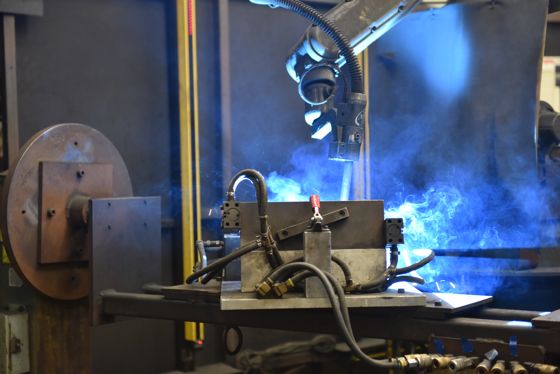

Welding, by both robotic and human masters.

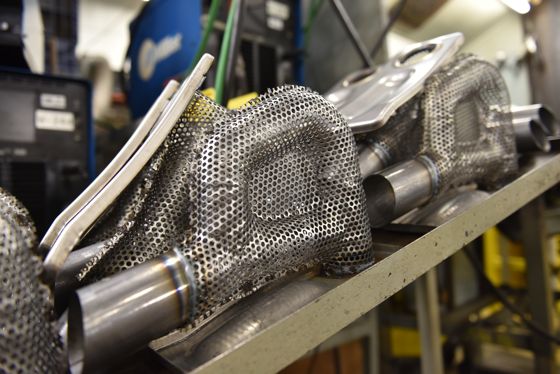

Headers for the 9000-series engines.

The internal portion of the muffler for the new 2019 ZR 6000R SX race sled.

Aluminum carved into steering and chassis components.

Thumbs-up for tunnels being prepped for the robotic self-piercing rivet assembly!

Welding a UTV chassis.

The Comfort Zone, aka the Sewing department, where seats and backrests come to life.

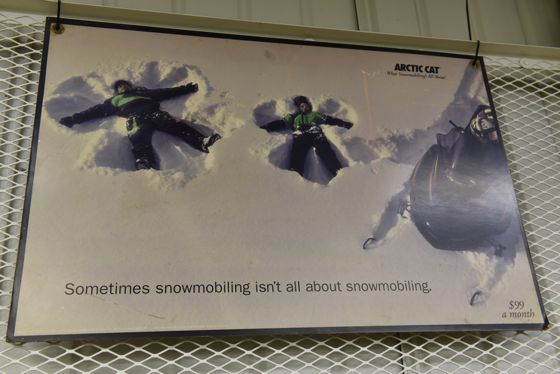

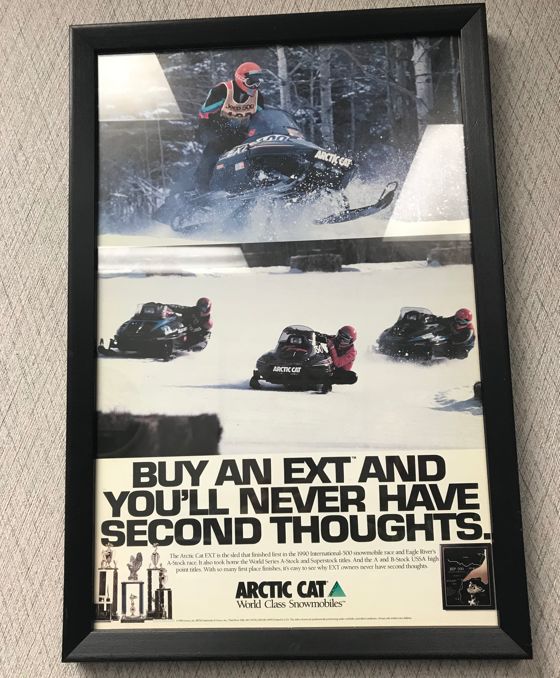

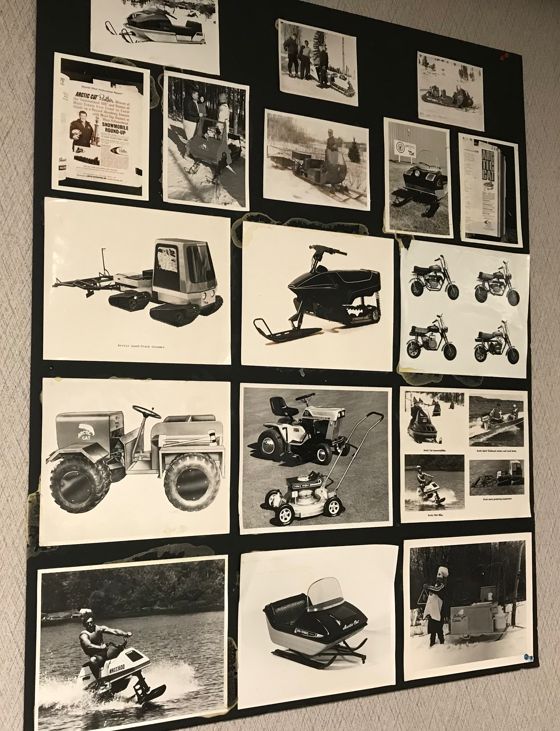

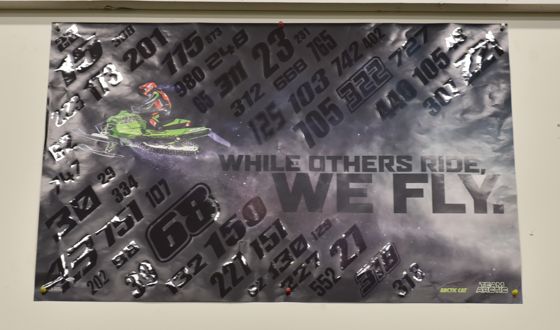

Thee are so many signs and posters on the walls there, including these gems below:

Those were just a smattering of the cool posters that hang on various walls within the company.

A sub-assembly area for rear suspensions. On this day they were building the XTRA-ACTION skidframes for widetrack Bearcat and Pantera XT models.

Wildcat XX models…heck yeah!

Wildcat Trail models.

After final assembly, every ATV and UTV is given a brief run before being loaded for shipping. Sweet helmet!

Bearcats at the end of Line 1, soon to be run, crated and shipped to a dealer near you.

Troy Halvorson has been integral to the company for as long as I can remember, with a variety of key Engineering roles over the years. A few months ago he took the Director of Operations position, which means he’s the guy responsible for production of all snowmobiles and dirt products. Smart, dedicated and always motivated, Halvorson is making the same kind of impact in this role that he did as a snowmobile engineer.

Ummm….I didn’t see this sign until after the factory tour. Sorry.

That’s all for now, thanks to everyone in TRF for all the great conversations and interactions on yet another great trip for me.

And thanks to y’all for reading and following along on this story.

Thanks John for another great story at the factory. Love these stories. I would love to be in on that meeting! Those posters are great. The Tigershark poster really caught my eye. I’m a snowmobile guy and not a water guy but this summer I purchased two used 1997 Tigersharks. Of course they both blew up on the 2nd ride. I knew nothing about these machines or even what to look for before purchasing them. They were so fun that I decided to spend the money and have new rebuilt engines put in them. These things are a blast! Still prefer snow though and can’t wait to ride the new sled.

Thanks John for the tour .Its always interesting what going on in the plant.i try to go every two years.

Great story John! It lives up to the “Insider” tag line! What does Cat do with the display models once the season is over? The purple Mountain Cat would look right at home in my garage (Spotted the same sled at Haydays..beautiful!).

You always do a good job John.

I have enjoyed your site for many years.

Keep up the good work

Love the Plant tour photos every year you do. Keep up the good work!

I hope those top secret engineering meetings are going to bring us a new chassis, I need something hardcore for us trail guys. Still haven’t found a replacement for my snopro chassis and yes, I have tried a procross, it’s not the same.

John,

Like the others have posted, the typical great work from you for the rest of us on the outside.

In the poster section, under the EXT ad, the poster with the several various AC products/prototypes over the years, the ‘snow runner’ type of sled with a single ski, can anyone add to the description of it?

Thanks,

Always cool to see your racers number on the poster…..

Great read and pictures again John…just when I think you are starting to slip you pull a rabbit out of the hat again..lol. I was up there a couple times in the padt month and the first time they were just working some bugs out of the robotic machine for the Alpha One skid’s, looks like they got it perfected.

Thanks John for posting this! That picture where the employees are in the meeting room discussing the future models gave me chills! So cool!

Can’t wait ! new winter new sled!! As always cool stuff from John!