ADAPT CLUTCHING INTERVIEW WITH KYLE OLASON – MECHANICAL ENGINEER, DRIVETRAIN DESIGN

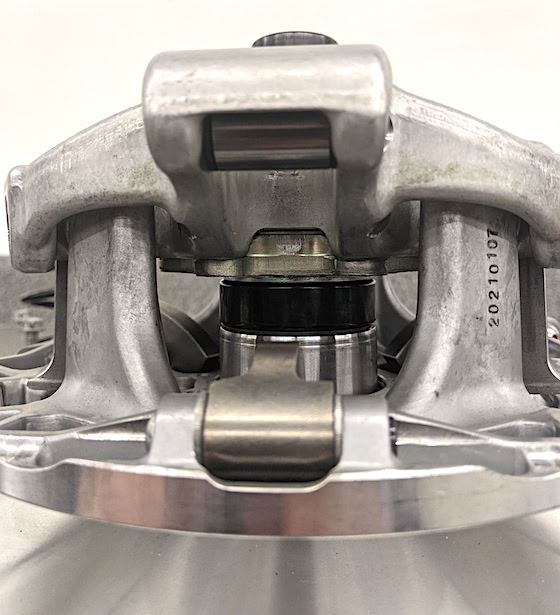

Im sharing this interview again for those who missed it the first time when it was included in the 2022 ZR 8000 models overview story, and for those of you who asked for more photos, Ive added them to this interview. Kyle (Olason) sent me these comparison photos showing the new ADAPT drive clutch compared to the current TEAM drive clutch. Seeing these photos, I share Kyle’s excitement, and feel good knowing Arctic Cat is innovating.

I got a chance to sit down with Kyle Olason, mechanical engineer in the Arctic Cat Drivetrain Design Group to ask a few questions.

AI: Kyle, what is ADAPT?

Kyle: ADAPT refers to the new CVT system as a whole (drive and driven clutches, and belt). The biggest innovation focused on the drive clutch which we’ll get into. The drive belt is carry-over from Model Year 2021 models. Driven clutch, while new, retains similar mounting and system to current production.

AI: Why ADAPT?

Kyle: The new clutch system is an effort to internalize the design of a critical component within our vehicles. The new system retains the idler bearing method for automatic belt tension which debuted on the MY17 9000-series snowmobiles and MY18 6000+ series snowmobiles. When bringing the design back to Arctic Cat, there were opportunities to get creative.

AI: And those opportunities to get “creative” were what?

Kyle: This is a three-fold answer:

1. Our past solutions in the drive clutch have had the torque transfer buttons aligned with the cam arms, and this set a parameter of minimum width possible for the moveable sheave. By moving the torque transfer to a different location from the cam arm/roller, the width of the clutch became a focus to utilize space more efficiently.

2. Concepts showed moving the cam arm radially outward from past designs would allow the spring to nest deeper within the spider.

3. Unique spider design allows for the spring to nest inside much of it while transferring torque and reacting to the cam arm load.

AI: And the benefits were what?

Kyle: While it started off as a study of “What is possible”, much of the unique aspects were able to be retained.

1. 1lb. lighter than current production

2. 5% reduction in inertia

3. Compact design with ~25mm or 14.1% reduction in width

4. Our goal related to belt life is to keep performance from our current product. We have had good belt life with our MY21-previous system. The idler drive system ensures the belt deflection is consistent throughout life while maintaining that low starting ratio.

5. Maintenance: The goal is zero-to-minimal service. The pocket in the spider above the cam arm can make inspecting for wear easier

AI: Will ADAPT retrofit to past models?

Kyle: Yes. Consumers wishing to retrofit ADAPT will have the opportunity this Fall when available.

AI: Will ADAPT add any top speed?

Kyle: Not necessarily top speed, but you’ll see a quicker throttle response and acceleration

AI: Thank you for taking the time to answer a few questions. I appreciate it.

Kyle: You’re welcome!

Are the service parts going to be available, specifically the idler bearing?

Whats up with the witness marks on the spider? Looks like the cam made contact under the roller.

I’m a little slow.

So these will mount up to a 2019 M8000 no problem?

And are less likley to explode like the 2019 clutches?

Whats the guarantee of these not exploding in 3300kms pf use?

Use the same belt as the 2019 as well?

Lastly, cost and how long to get if I was to order these?

Will the drive spring and weights be different. Any of the old team clutch components work?

Ryan Rexin – The answers I have for you are the same as the ones in the interview. ADAPT retros back, uses same belt, available in the Fall of 2021.

Pricing has not been announced, but Id assume its in the ballpark of whatever you’d pay for similar clutching replacements.

Awesome news do you need to replace both drive and driven or will the new drive clutch work with the Team driven ?

The only question i have, is why didn’t they go the extra step and put rollers in place of the slider buttons? Maybe that’s a future step? Hope they are not made in china, otherwise it’s a step backwards.

I hope Arctic Cat has learned their lesson from using bad aluminum alloy into clutches.

And that the ADAPT clutch is made of higher quality aluminum alloy.

I like that the rollers and weights should be easily replaceable and there is a 1lb weight savings. How do you separate the spider from the assembly? I would guess the 3 pins the hold the 2 pieces of spider together will be impossible to remove several years down the road but not sure if you will need to take the spider off on this clutch. How do you replace the bearing on the main shaft that the belt rides against?

Those weights are HUGE! But I like that they can’t shim side to side if set screw comes loose-in fact I don’t see a set screw – Even Better!!!

Will this set up work on the 2012 turbo? Is 10,000 miles on an untouched primary a good time to change it?

You would have to change everything out then try to figure out what belt would work on it Flintstone. Jackshaft, Primary etc.

If the improvements and direct bolt on they are suggesting are a big improvement over the Team system that I currently have on my ’17 ZR 6000R XC, I might upgrade? But only IF the Price Is Right. If the improvements are minor and the costs are too high, I will just stick to my current clutching systems and use an aftermarket kit?

I take it this another sliding button arrangement?

How much of a difference in acceleration? Will it noticeable enough to justify replacing my original? I have a 2017 T-Cat with zero clutch issues and put 4,000 miles on the original belt, so my clutch is not of any concern. However, my brothers 2017 turbo clutch was warranty replaced.

I had over 14,000 miles on my ’12 Cat clutch, with no issues. My ’16 Team primary had bad rollers with only 6,000 miles. The Team was supposed to be an improvement. I hope these new ones are made in North America instead of a foreign country that doesn’t even know what a clutch is.

Clutches. We’ve been having issues since the beginning of time it seems. Doesn’t seem to matter what version we get there’s always issues. And I have had them all. I thought the Team ones were supposed the solution to our problems. Hopefully after 60 years this version they get it right.

I want to blow it out once a year and not touch it for 10,000 miles.

Great explanation of the new clutch that everyone is talking about. Thanks for the images and info!

Thanks Russ, I figured it was still good!! Some might question my love of a 2012 sno pro on a rough night!! I’ll show you! It’s the best sled I’ve ever rode in on the whoops on rail road grade that’s there is no ends to them, this baby delivers

Kale Not that it’s important but you reference the MY17 thundercat has the roller bearing clutch on it The MY17 RS600 (Roger Skime) also utilized that clutch I have one and sold 4 others at my former dealership

I think this is going to be a nightmare just like the 2012 50th anniversary release. Gonna be nothing but issues.

Bill Christianson – I forgot about the 2017 RS600 great catch.

George O Safford Jr. – C’mon Man!

Appears that the Spider “Halo” is a forged unit? Almost everybody said the Yami clutch is a superior design (remember the critics saying how the Winder will be better than the TCat in ’17 due to clutching?) This new clutch has many of those features. The rollers can be serviced without disassembly, the weights do have side shims which will prevent galling of the steel weight into the aluminum. Is the button clearance adjustable for wear?,, looks like it is accessible when the roll pin is removed. I would not hesitate to make the move to this clutch.

Performance is important…. Nice to read about the enhanced performance.

Now, think about how the designers can narrow up the bodywork of the sleds….

Hopefully they will make the clutch in a 30 mm taper

Will I need a new complete alignment tool? or just a different button for the primary.

Will my blue clutch puller work?

Kale, Thanks for the Pics ! Only reason I was gonna run to Ken’s Saturday . Was to look at the new clutches . Don’t care much about new stickers and paint ! Looking at the pics . Do we need a new grunt tool ? To take it apart ? Or is it just screwed together ? Tom S , mention blue clutch puller . The first ones were painted green. On that note . If there is and special tools we need for these new clutches . ( To take them apart ) Can you post it with part numbers ? That would be much appreciated . Hard to race a new sled with out the right tools ! Been down the road before !

Kale,

I have a 2017 ZR 6000 RS and a TCAT 2020. I can tell you that my 2017 RS 6000 never came with a roller bearing in the primary and I bought it brand new. My TCAT that I bought brand new has the roller bearing in the Primary.

this smells like Yamaha ‘fixing things’ for some reason or another

anyone seen the 2021 parts fiche for Cat and Yamaha yet?

tspencer22, the Thundercat/Yamaha triple 998 is 30mm