When I think of product development, my mind typically shifts to engineers focusing on a new holistic rider platform like the 2024 CATALYST. Speaking for myself, it’s easy to get caught up in those marketing launches, and sometimes the big flashy objects overshadow other really cool product R&D of smaller components if you don’t pay attention.

This scenario hit me square in the face after seeing the Tiger Slide Wear Strips in the 2024 Snow Accessory catalog. Curiosity peaked, I set out to see what I was staring at, which led me to some great insight from Guy Sibilleau (Mechanical Engineer IV) and Peder Erickson (Sr. Product Manager).

I truly wanted to find out WHAT STARTED THE PROCESS AT ARCTIC CAT TO DEVELOP A BETTER WEAR STRIP? So, I began the interview with that exact question.

After learning about these, Ill be adding a set to my ZR600 129 Catalyst this winter. -Kale

Guy Sibilleau: This dates back to 2003, I invented the Vespel high performance wear strip during my time with another manufacturer. Back then, I wanted to eliminate the need for bogie (idler) wheels on the rear suspension slide rails. In the late 60s, Arctic Cat’s Lowell Swenson and Roger Skime revolutionized skidframes by eliminating bogie wheels with the invention of the slide rail suspension, which every OEM utilizes today. On today’s late model snowmobiles, the sole purpose of bogie (idler) wheels is to reduce pressure between the track clips and the plastic wear strip in strategic locations. My goal was to make snowmobile rear suspensions bogie-less once again. Fast forward to 2016, I joined the Arctic Cat Snow Engineering team.

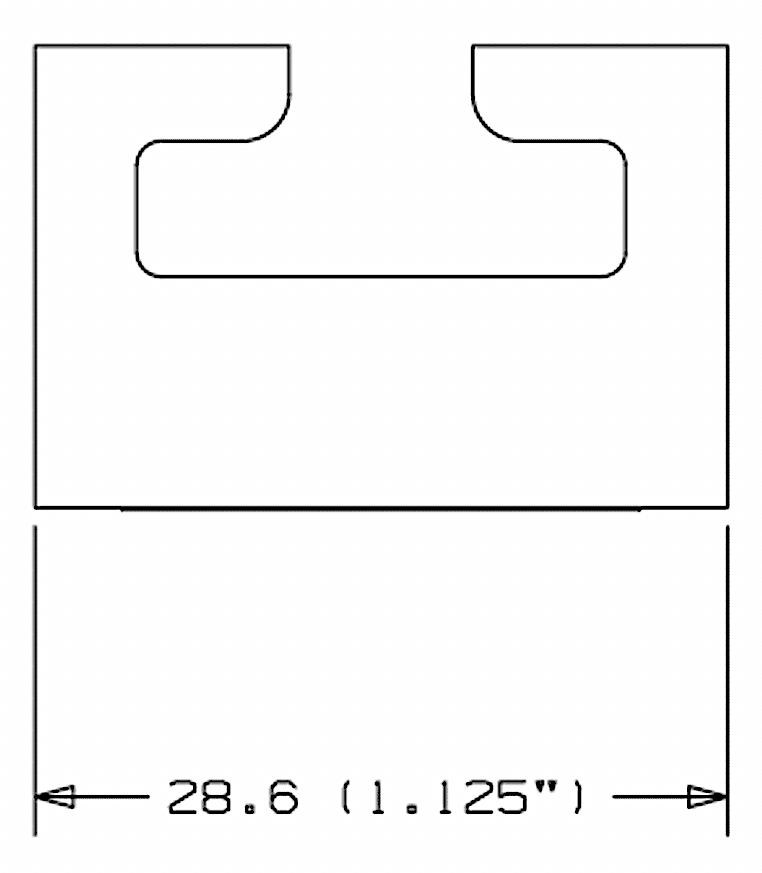

Peder Erickson: In 2019, after the launch of the revolutionary Alpha One single-beam rear suspension, we identified the opportunity for a new high performance wear strip. The Vespel wear strip is wider than the standard Arctic Cat 1.125” profile, making it incompatible with this key segment, so we set out to expand our range of fitment with this product. Improved knowledge and advances in material science since 2003 made it possible to incorporate several other changes to push performance boundaries.

WHAT WAS THAT PROCESS, WHAT DO TEST PARAMETERS LOOK LIKE, AND WHAT WAS THE DURATION OF TIME FROM CONCEPT TO PRODUCTION?

GS: I started working on the Arctic Cat high-performance wear strip in 2020. Early on in development, we conducted extreme durability testing to develop a baseline. The tests were performed in controlled, dry conditions on a paved track to test different varieties of high-performance plastics embedded into the wear strips.

Thermal imaging and other data collection methods were used to record temperatures of the track clips and wear strips over specific speeds and distances traveled. Once an insert material was chosen, design refinement continued to account for the various manufacturing processes involved. And finally, parts were put through durability testing in which machines equipped with the wear strips are exposed to as many real-world winter riding conditions as possible.

PE: After 3 years of conception, development, and proving the design met all our objectives, Tiger Slides high performance wear strips were launched as a MY2024 accessory.

WHAT IS THE DIFFERENCE BETWEEN A REGULAR WEAR STRIP AND THESE? WHY SHOULD I BUY TIGER SLIDES?

PE: A conventional wear strip is made of 100% ultra-high molecular weight polyethylene. (UHMW-PE) This is a very durable, low-friction material on its own, but for tough snow conditions, high speeds, or lots of miles, some riders demand greater performance from their wear strips. To make these components last as long as possible, we need to lower their operating temperature by reducing the friction generated by the track clips as the track rotates. Tiger Slides use 60-degree molded inserts to extend the life of both the wear strip and the track by creating and absorbing less heat.

GS: A term used in tribology (the study and application of friction, lubrication, and wear principles) is limiting pressure velocity, or LPV. This factor represents a material’s ability to withstand contact pressure and sliding velocity. UHMW-PE has a very low LPV factor relative to a material like Vespel, which has a very high LPV factor. By incorporating inserts of a higher-LPV material, the track clips generate and transfer less heat on contact. Tiger Slides utilize inserts made of an advanced type of very high-LPV material which is more pliable than Vespel. This improves the durability of the inserts to withstand impacts and debris. Their 60-degree angled arrangement was also strategically chosen to increase effectiveness.

PE: We also wanted to give Tiger Slides a look that stands out to match their performance advantages. Each piece is molded with a custom blend of black and white UHMW that reminds me of the classic leopard print seat—Bold and distinctly Arctic Cat!

IN GENERAL, HOW CAN A CONSUMER GET MORE LIFE OUT OF THEIR WEAR STRIPS? WHAT’S AN AVERAGE LIFE EXPECTANCY, GIVEN THE SNOWMOBILE IS RIDDEN IN NORMAL SNOW CONDITIONS?

GS: Simple things can be done to keep wear strips from wearing prematurely:

Keep the correct track tension—A track that is too tight, too loose, or misaligned can contribute to accelerated or unusual wear.

Maintain adequate ski pressure—Letting out the front limiter strap too much will result in high pressure at the curved part of the slide rail, concentrating the weight of the snowmobile in a smaller area and leading to uneven wear and shorter life.

The Tiger Slide high-performance wear strip lasts approximately 4 to 6 times longer than a conventional wear strip, subject to the individual riding habits and terrain conditions.

INSTALLATION – SAME, HARDER OR EASIER TO INSTALL?

GS: The installation process is the same. The difference is in the preparation of the wear strip for your specific snowmobile. The Tiger Slide high-performance wear strip is designed for a universal fit. It will accommodate 121” to 165” track length rear suspensions, and must be cut to length and chamfered as needed. A series of holes are pre-drilled for ease of preparation.

PE: Instructions are included to guide the user through setup. By using the old wear strip as a template, the process of replicating the features needed for any given model is simple and straightforward.

WHAT IS THE BEST WAY TO INSTALL NEW WEAR STRIPS?

GS: The Arctic Cat-recommended method to replace wear strips is to remove the rear suspension assembly from the snowmobile. This allows the most room to work and gives the user a chance to inspect for other worn-out or broken parts and perform routine maintenance.

HOW FAR BACK WILL THE TIGER SLIDE WEAR STRIPS RETRO TO OTHER ARCTIC CAT MODELS? WILL THEY WORK ON OTHER BRANDS?

GS: The Tiger Slide high-performance wear strip will retrofit Arctic Cat rear suspensions as far back as 1995 equipped with 1.125”-wide profile wear strips.

Certain models use a wider 1.5” wear strip profile; Tiger Slides are not advised for these applications.

PE: The Tiger Slide high performance wear strip is also compatible with Yamaha models which share the 1.125”-wide T-slot profile wear strip.

WHEN WILL THEY BE AVAILABLE TO PURCHASE?

PE: Tiger Slides are available for order now (Part number 8639-422; sold individually) and orders will begin shipping early Fall 2023!

I tried the Vespel hyfax a few years back on a 128 skid, and since they were supposed to be more effective, I replaced my 5.6 skid wheels with 5.3 wheels kit advertised for better speed and efficiency. Did not gain any speed and the Vespel hyfax showed more wear then a normal set. So went back to standard wheels and hyfax, Are these new Tiger hyfax different enough to perform better than then the older Vespel?

I bet you track clips turned blue and fell off also. Running heat through the track bars will degrade them and break them also.

Yes, these will burn the clips right off your track, turn them blue first. Your said exactly what I was thinking. Been there, done that, got the t-shirt and hat…..and a new 780.00 track.

Re-inveting the wheel here again on this one….

“I replaced my 5.6 skid wheels with 5.3 wheels kit advertised for better speed and efficiency”. So you went to a smaller diameter wheel and expected to reduce drag?

Those look alot like the Dupont Vespel slides.

Are they similar or totally different?

Can wait to see the finished product.

To answer your, and Krom’s question, the outward appearance may look similar, but these Tiger Slides are different than what Yamaha has offered. Peder and Guy make references to the strategic 60-degree placement of the inserts on Tiger Slides, and although Im not well-versed on Yamaha versions, I believe those to be a 45-degree placement. Neither Peder or Guy giveaway any trade secrets on materials, but do make mention there have been improved knowledge and material advances, which lead me to believe there are more differences between Tiger Slides and Yamaha’s.

I have over 11k on my OEM Cat hyfax, and they still look new. If these last 4 to 6 times longer, I’ll never have to buy another set before I retire from riding.

Holy smokes! 11k? That’s pretty incredible.

Wearstrips are just that, a wearable component. Cheap and easier to change than track clips. Idler wheels are not only there to extend wearstrip life but to prevent derailments. I also know that vespel expands and contracts at different temperatures than polyethylene. That means they are going to fall out once you see an extreme condition. The grooves that they leave behind will probably help catch snow and water though, so you got that going for you.

If these slides are truly the “cat’s pajamas”, are they going to be incorporated into all production 2024’s or at least all 2024 production Catalysts?

Or by making them accessories, will the consumer be performing in-service product development / durability testing?

Mmmmmm? On wear item components like slides, I doubt you will see these versions on production units unless the buying public is willing to pay for the feature. As for the second half of your question, based on Guy and Peder’s responses on development/test times, I feel AC has done their due diligence in testing to bring these to market. That said, I also believe when we as consumers buy ANYTHING, we are real world “field testers” and the development cycle continues.

It’s the same in software development (which is my profession).

But if they truly offer up a significant improvement in wear resistance, why wouldn’t Cat make them standard equipment?

Don’t understand your logic.

Because they list for $159.99 a slide on country cats web site.

But if they are as great as they are being portrayed to be, shouldn’t they buy their way in? Also, economy of scale- if Cat installs them as an OEM part on every sled built vs an accessory, the cost drops, possibly significantly.

One could ask the same question about almost anything in the accessory catalog – bumpers, hitches, windshields, tunnel bags… anything. And the answer is, it comes down to cost.

Even if it’s generally agreed to be better, even if buyers willingly pay the extra price, Cat would still lose sales to competitors who don’t offer those options and sell cheaper.

It’s amazing how many times a sale is made on price alone without regard to what you’re getting for your money. It doesn’t make sense, until you see it with your own eyes.

I consider the “hifax” to be an integral part of the baseline sled (without it, couldn’t operate the sled) unlike the other items that you list which truly are accessories.

If this new design is as good as Cat says it is, they should make it standard. Economy of scale will reduce the cost.

BTW, do you really think that the new “hifax” costs Cat $160 to manufacture? I’m guessing it reflects a significant mark-up since it is being marketed as an accessory.

Do they fit the alpha rail? Or does it have holes already drilled for them too?

Kale,

What is the difference between these and the yamaha vespel wear strips ac has been selling for 4 or 5 years now?

Read the article. States right in there.

According to the article, the angled inserts are not Vespel, but a very high-LPV material that is superior to Vespel.

The main body of what historically has been called hifax is manufactured from ultra-high molecular weight polyethylene.

Something has to wear. Take your pick. Wear strips, or track clips.

these would look just bitchin’ on a 7000 with a Tiger Striped seat

only problem I see is hoe they are mounted (lots of screws ) that could back out and cause major damage or if the slides wear enough the screws will trash the track. Why try fixing a non problem anyways. Current sliders work greast are cheap and last a long time as long as you use scratchers.

Well? To your point, there is nothing wrong with a standard slider, but if we didn’t improve upon things, we’d still be riding bogie wheel “suspensions” versus slide-rails.

Well… Here is another off the wall question. Will they work in a skidoo rail, like say a 2023 XRS?