Yep, the crazy-warm spell that hit most of the country did serious damage to the ditch riding in TRF. Less than a week earlier, this section of Hwy 59 would have been ridable.

The billboard on the outside wall of the Arctic Cat factory.

First stop: Marketing dept., where Kathy Johnson continues her boycott of allowing me to do an interview with her for this Website. And she still gets mad whenever I sneak a photo of her as she helps coordinate marketing opps.

Fresh off of organizing the snowmobile dealer show, Gary Nelson (L) cracks his knuckles while diving into organizing the upcoming ATV dealer show.

Meanwhile, Pat Hanson (R) cracks a wry smile at the prospect of hauling show machines to various locations in the next few months. While he officially operates transport for Arctic Cat shows, press events and the like, Hanson is a jack-of-all-trades who also rides sleds and ATVs for the camera; fixes broken equipment at events (including stuff that I unwittingly break); and keeps the play toys running at their optimum.

Having migrated over to Engineering to find Joey Hallstrom (R), I caught a conversation between him and Doug Wolter (L, Director of Snowmobile Engineering); Dale Hahn (tan pants, NVH engineer) and Keith Homstad. While I’d like to say that the conversation was ONLY about snowmobiles, I think the subject of hockey came up, but only momentarily.

Joey and I took a tour of what’s going on in Engineering, with a stop in the Styling Department, where Corey Friesen was applying his artistic expertise to several projects. However, the conversation quickly turned to the 5th Annual Arctic Cat Hockey Night: Quest for the Cup hockey tournament.

Joey was throwing down the gauntlet, so to speak, and making outstanding proclamations about his goal-scoring prowess.

In addition to playing goal, Friesen organizes the Arctic Cat Hockey Club and the tournament, for which he produces a sweet flyer he’s shown holding in this shot.

The Arctic Cat Cup will get its own post within the next day!

Later in the day, while walking through the machine shop, I ran into Kirk Hibbert (L) and Ron Black. Kirk was working brake components for Tucker’s race sled on a lathe, while Ron was talking about engineering projects connected to the Wildcat UTV. Back in the 1990s, Ron was Kirk’s race mechanic, so these two have seen and experienced lots of stuff together.

MUCH later in the day(at 10 pm to be exact), out at his race shop, Hibbert was still working brake components on a lathe, getting stuff ready for the Lake Geneva and Clash of Nations (Sweden) races.

For the better part of the day, Kirk worked on turning some brake discs and cutting shims for some ideas he’s testing, all part of comprehensive effort to continually develop race sleds and win races.

With the switch from the former, highly-developed, Wilwood master cylinder and jackshaft-mounted caliper to the new Hayes Radial Master Cylinder system with the disc/caliper located on the driveshaft, Hibbert and others are working to find the exact feel and power they’re accustomed to when they grab the lever.

Kirk is a firm believer in a driveshaft-mounted caliper, having first developed a system on the 2002 Sno Pro racer (the precursor to the Firecat).

Two shims done, one to go…

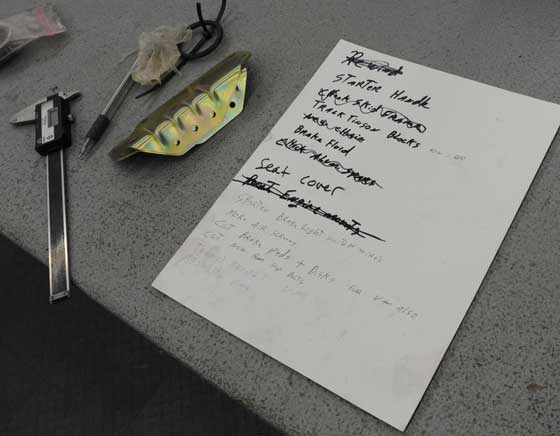

Kirk’s to-do list for Geneva/Sweden. Man, what I would give for a collection of to-do lists from Kirk, Coltom, Thompson, Dimmerman, Scheele, Nelson, T/S Racing, etc… How cool would that be!?!

I paid the Hibberts a lot of money to get the Presenting Sponsorship package on their shop tool box. Definitely a worthwhile sponsorship.

Friday morning, bright and early and in Troy Halvorson’s (L) office, where he and Ron Bergman were discussing the pros/cons of various track lengths.

These guys are dutifully-aware that race track competitors are racing with 128-in. Arctic Cat tracks.

Later, in a different area of Engineering, a crew looks at an evolving prototype tunnel protector system for the ProCross chassis. From L-to-R: Bergman (background), Zach Evans, Kevin Schindler, Rod Foss and Mike Larson.

As is the case with most developments, the crew discusses the merits and potential drawbacks to a certain design, sprinkled with new and creative solutions.

I’m always impressed with the creativity of engineers, as well as their ability to see all aspects that affect the development of a single part. In the case of the tunnel protectors, they discussed everything from ease of installation (will customers accept removing the rear arm bolts to swing the suspension/track away from the tunnel?) to fit/finish (should the protectors be affixed via rivet, bolt or neither?) to cost.

My head flush with ideas, I went back to the Marketing department where I saw Rick Stokke working his magic in the international sales arena.

And in the break room, Dean Lawrenz (L) and Gary Flynn were putting the wraps on a discussion about service information for international markets.

Both Lawrenz and Flynn have been at Arctic Cat for decades, and both graciously agreed to be interviewed in the coming weeks. Stay tuned!

In the afternoon I headed down to what’s referred to as the “ZR Shop,” where race sled development occurs. Sure enough, development was in full-swing as Brian Dick (L), Michelle McCraw (middle) and Dayne Efta were busy assembling a Sno Pro 600 test sled that incorporates some ideas that have surfaced during the race season.

It’s amazing that these three have literally memorized nearly every part number on the sled. Seriously, they can rattle off the part number for every rivet, nut, bolt, etc… as if it were their phone number.

Working day-in and day-out with them, these machines become their “children” so to speak, about which they know every detail and nuance. It’s very cool.

I made Brian throw down a pose with the sled that he’d raced in Pro Open the weekend prior, at the USCC season finale in Warroad, Minn. The sled sported some new ideas and componentry that Engineering and the Race Department wanted tested, and that proved both successful and productive (Brian finished fourth).

This sled and the one that was being assembled were slated for more racetrack testing this week, followed by more testing out West in the coming weeks and months.

And so the evolution of future race and customer sleds continues. Winter may have ended in TRF, but the riding/developing never stops with this crew.

Thanks for reading!

Hey, what it the part number for the windshield on Brian’s race sled? I like that windshield. Thank you for another great TRF story/pics!

Kirk looks like Santa in his workshop….ha

I have a “to-do list” I was given by Bryan Dyrdahl’s crew at the I-500 in 2007. I was running a Ski-Doo and, while we had a plan for our maintenance, I swung in to talk with them and see if maybe we might be overlooking something. Bryan had gone out with a cold-seized engine the first day and his mechanic, Jim Boe, said, “Here’s our list, we won’t need it,” and handed it to me. Kept it ever since. It’s not very often you get an I-500 maintenance checklist from one of the greatest cross-country racers ever. 🙂

Todd U: The part number for the windshield on Brian’s sled: 6606-513 WINDSHIELD,TALL-SMOKE (XC)

Im very upset with Cat as of yesterday! Drove by my cat dealer yesterday and turned right around to stop and find out what the heck was going on. All the creats and sleds and atvs were gone. So I talked with the owner and he said that cat wanted him to order 20% more sleds and atvs then last year. So he had to drop the franchise cuase he lost over 100K this last winter becuase we had absulutly NO Snow. He still sold 70 sleds this past year but just could not justify lossing more. I am one of those that bought a new sled from him. The dealer is about 5 miles from my house. I have bought many new sleds and parts from him for years. Now the closest dealer is over an hour away. I dont know what Cat is thinking! But with the current econamy why would you not work to keep a dealer around. I know that 70 sleds is not a lot but now that is 70 less for next winter. Plus posible loss of customers becuase of having to spend more on gas to travel to get sleds serviced and warranty work done. Very disapointing Arctic Cat!

So the engineers looking at the cooling system… is this the same crew who designed the 2012 Procross cooling system? If so, I certainly hope they tried their “new design” in the cold and snow, and not just on the floor in the warm shop.

Ed V.- The same thing happened in the Adirondacks of NY. Arctic made three Cat dealers order so many sleds after a couple of lean years that they forced the dealers out. In the Saranac Lake-Tupper Lake area, where there are some excellent trails and abundant snow, an Arctic customer now has to drive 40+ miles south through the mountains to get parts or service. Passing 3 BRP, 2 Polaris and 3 Yamaha dealers in the trip. Its unreal. Its a good thing so many of us are loyal to Arctic because they don’t make it easy!

Sucks that anyone has to drive further to find an AC dealer, but I find it funny that everyone thinks its ALWAYS ACs fault that the dealer went out of business.

There are 2 sides to every story and you may only be hearing one of them.

First, for the story itself… great job. These are my favorite kinds of stories on here because they focus on the real people behind the product.

As for the concern about another AC dealer closing, I certainly don’t know the facts — but it is concerning because I have heard (and even seen) this kind of thing many times. Again, one of the great things about AC is the people behind the product. This includes the smaller dealers too.

Joey playing hockey? Uffda! What’s this world coming to?

Still waiting on that interview with Kathy!

The old Crossfires built up a lot of ice under the tunnel too. Just carry a BFH to knock it off before riding the next day.

Great articals, Always love reeding your stories.

I would wish to thank all the HIBERT family for all they have contributed to Arctic cat over the years.

Many hours goes unnoticed,THANKS

Certainly enjoyed the story and the pictures.. Thanks.

I have purchased 5 new Arctic Cats in my life. All 5 from different dealers because when I was ready to buy the next one, the dealer was either out of business or not selling Arctic Cats anymore. I heard the same stories from dealers about being pressured to take on more stock than they are comfortable with. I went to the 50th and I really like the people in TRF but there seems to be a disconnect between them and the dealers. I love sharing their passion but their making it difficult.

In the Hudson Valley in NY we have lost 4 Arctic Cat dealers. A couple of them were stand alone Cat dealers and had to fold up the dealership due to the same scenario the others are saying, Cat insisting on huge increases in inventory. The other two still sell BRP and have taken customers from Cat with there product and convenience of location. There are two huge dealers left in the Hudson Valley and a new one recently opened. It would appear that Cat wants a dealer to sell a couple hundred sleds or doesn’t want them to be a dealer. I know others in the northern Adirondacks who’ve also questioned this practice.

“Spring is here…time to start thinking about next winter!”

tell us more about that handlebar jack stand

I sure hope those gurus in engineering are working on a fix for the belt issues these M and XF High Country sleds are having. I am not just talking about the shim update either. They will not sell many up here in AK if a solution isnt available by fall. Go Team Green!

Gdub,

I agree with your assessment of engineers. A lot of them are “book smart” but lack any practical knowledge.

P.S. At work we run into the same problem with Boeing aircraft.

When did Troy cut the long locks?

Greg H,

I have an old crossfire – the icing on the ’12 Procross pales in comparison to anything I’ve ever seen. It’s dangerous.

What I don’t understand is how this (and other issues) were not evident during the real-world testing of these machines. I rode my sled 6 days this winter. Encountered the icing issue, worn hyfax, and clutching within 2 days of riding (in pristine conditions I might add).

How could they miss this stuff?

hibberts don’t use the rr brake rotor?

My dealer said wait to order new sled they might let the franchise go. A year with NO snow and Arctic Cat told them they had to increase there order from last year. I thought only companys like polaris did that. We live in a rural area,gas is expensive if thats the kind of Company Arctic Cat is getting to be Ill drive something else! Dont stab your dealers in the back to gain Market Share!!

Gdub,

My Crossfire was an ’09 which had the shorter tunnel. Icing was a big problem because the heat exchanger was above where the track goes over the upper idler wheels. If I didn’t knock the ice off with a hammer each day before riding, the track was literally locked solid.

On my new XF800 Sno Pro, the tunnel is much longer with the heat exchanger above the rear axle of the skid frame. Therefore, I did not have much problem with icing. However, I was still careful to make sure it was cleaned out good before parking the machine for the night. In talking to some of the fellows from Cat at the Sneak Peek snowmobile show in Minneapolis last Saturday, they said to wait on retrofitting with the new flat tunnel as possibly there may be a recall coming. Time will tell.

My new kitty performed flawlessly. Was very happy with it. My only complaint was several incompatibility issues on the accessories. You would think the engineers would have figured that some of us might buy more than one accessory.

Did you think to ask who won the 2012 snowmobile give away while you were there?

I hope they have update their rear suspension shock calibrations to match what scandinavian byers want. Recent years front end has been way too stiff at little bumps but in deeb bumps it bottoms out. Then rear suspension has always been stiff at low speeds but bottoms out when thing get serious. Lets hope the RR brings the Cat back in business.

Getting pet insurance is a great idea if you are the type of pet owner that will spare no exenpse if one of your pets becomes ill or gets in an accident. Veterinary Pet Insurance Co. (VPI) is the oldest and largest provider of pet insurance in the U.S. and wrote our first policy back in 1982 to television’s Lassie! Since then we’ve seen a lot of other pet insurance companies come and go, but we’ve managed to succeed by providing our customers with the most coverage for the least amount. The costs will depend on a number of factors any extras you might like to add such as cancer riders, wellness coverage, etc. You can get a quick and easy quote on our website and you would also qualify for a 5% multi-pet discount.To give you an idea of how pet insurance works, this would be the process if you were to file a claim with VPI:1. Visit Any Veterinarian you can visit any licensed veterinarian worldwide. Simply pay for treatment at the time of service.2. Submit Your Claim Fax or mail your claim form along with your invoices.3. Receive Reimbursement After meeting your policy’s deductible, you are reimbursed according to your plan’s benefit schedule allowance or the eligible invoice amount, whichever is less.With veterinary medicine becoming more advanced, it is also becoming more expensive, and many pet owners struggle with paying the resulting bills. With pet insurance, you still pay the bill, but you are then reimbursed a portion of the costs. VPI reimburses based on a benefit schedule which takes the guesswork out of figuring out what’s covered by telling exactly how much will be covered for any condition or accident. I hope that helps and good luck! Was this answer helpful?

I just pay the vet as I go along.With my last dog, I would have spent thousands more on pimerums than the insurance company would have paid out in claims, so it wouldn’t have been worth it. Was this answer helpful? http://hnrvxiongn.com [url=http://wzcsblfff.com]wzcsblfff[/url] [link=http://zdjzhcootf.com]zdjzhcootf[/link]

I di’ndt know where to find this info then kaboom it was here. http://zeobcvpzipt.com [url=http://splbsn.com]splbsn[/url] [link=http://jcxzqdshp.com]jcxzqdshp[/link]